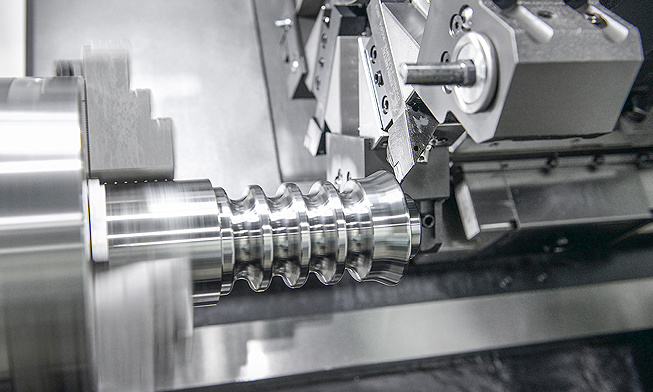

Materials and Manufacturing Processes of Automobile Fasteners

May 13,2024

The development of the tightening process technology of automobile fasteners and the threaded fasteners itself is based on the needs of connection reliability and structural lightweight, and is the result of the advancement of threaded connection design, process and material technology. The key to bolted joints is to control the axial clamping force of the bolts. In order to realize the accurate control of the bolt axial force, it must be guaranteed from various aspects such as the design and selection of fasteners, the control of friction coefficient, and the correct use of tightening methods.

The material of automobile fasteners

Most of the high-strength bolt steels are medium-carbon steels and medium-carbon alloy steels, which are all used after quenched and tempered heat treatment. After heat treatment (quenching and tempering), its microstructure is tempered martensite + carbide. After ultra-refinement of the austenite before quenching, it is proved that its mechanical properties can be improved. Compared with the traditional fine-grain heat treatment of steel, when the austenite is refined to less than 10 μm, all the mechanical properties are significantly improved. For high-strength bolt steel, only improving the strength and toughness or only grain refinement cannot fully meet the application requirements. For example, when the tensile strength of most alloy structural steels is increased to 1200MPa, delayed fracture will occur, so further increasing the strength will lose the use value and cause greater insecurity. From a practical point of view, improving fatigue strength and fatigue life is a particularly important and more arduous subject for improving delayed fracture resistance.

The improvement of the anti-fatigue performance of automobile fasteners is related to the improvement of the cleanliness of carbon steel, especially the change of oxide size and distribution. It is a difficult challenge for the electric furnace metallurgical process of producing this kind of steel, which requires the cooperation of all parties. Improving delayed fracture strength is not only related to grain refinement, but also related to steel structure and grain boundary state. Scientific research shows that when the austenite grains are refined to 2μm, delayed fracture is not better than coarse grain size. Delayed fracture is essentially a phenomenon of hydrogen embrittlement, which usually develops in the form of intergranular fracture, so it is easy to be delayed during use. hydrogen brittle fracture. The strength of developed secondary hardened steel is 200-400MPa higher than that of general quenched and tempered steel, which can be explained by cold working of steel. When the steel specimen is loaded to its yield limit, the load is quickly removed. In the secondary loading, the strength of the steel is obviously increased, but the plasticity and toughness exhibited are all decreased.

In addition, through microscopic observation, the atomic lattice distribution of the cold-drawn steel is more orderly and regular than the original, which also shows the improvement of its strength performance. While adopting electric heating treatment and cyclic heat treatment for austenite fine-grain heat treatment, the fine-grain effect of foreign steel is used for reference. Using segregation at austenite grain boundaries, the grain boundaries of atomic phases are strengthened by low-energy electron diffraction and grain boundary temperature calculations.